The Zotefoams difference

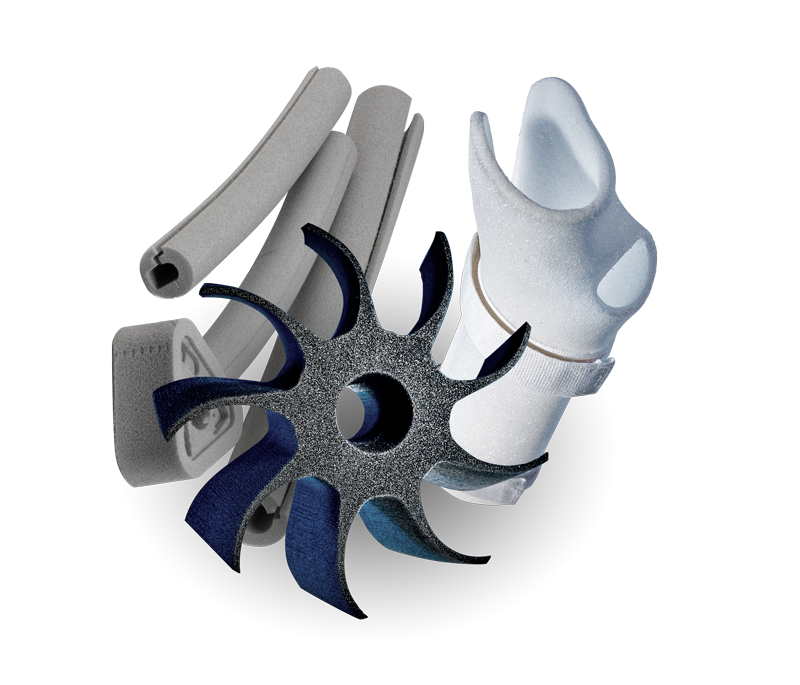

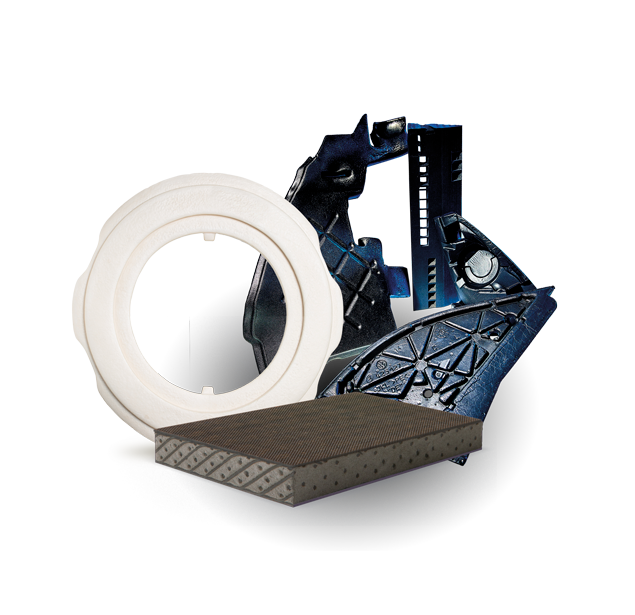

Zotefoams manufactures a wide range of lightweight, crosslinked block foams using variations of our unique nitrogen expansion manufacturing process. This affords an exclusive combination of beneficial characteristics – uniformity, purity, low toxicity and durability – that differentiates Zotefoams’ materials from all other foams.

The unique, uniform cell structure of Zotefoams materials makes our products a critical component in a world of everyday applications.

View the webinar to see how Zotefoams materials are made >>

A unique manufacturing process

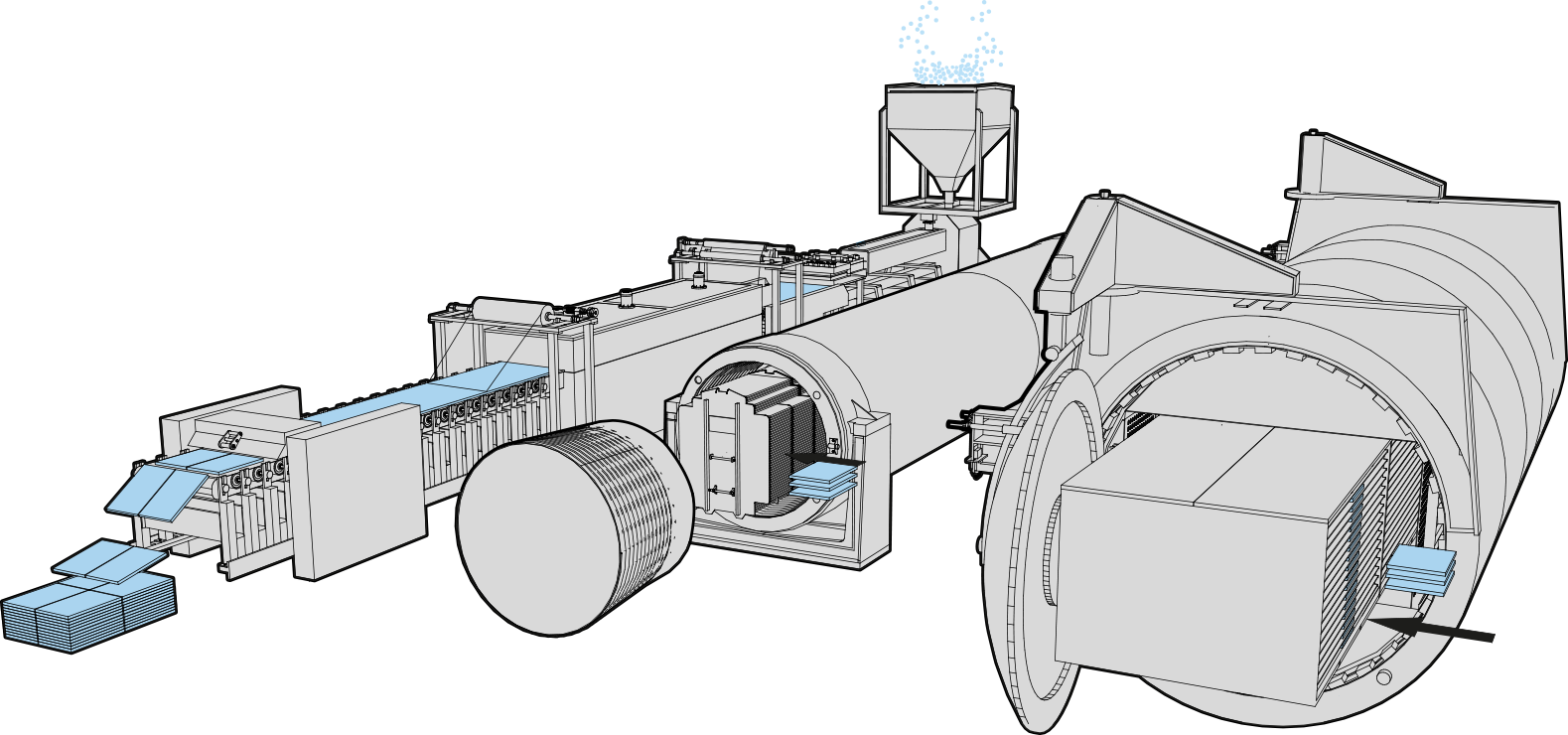

Zotefoams produces high-performance, closed cell, crosslinked foams from common and engineering polymers using temperature, pressure and nitrogen borrowed from the atmosphere. The combination of foaming process and polymer performance delivers properties such as excellent fire resistance, high-temperature stability, toughness and insulation, which are prized in a wide range of demanding applications.

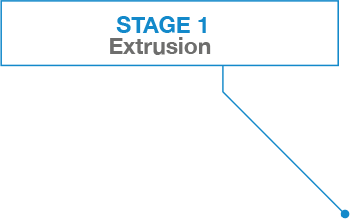

Stage 1

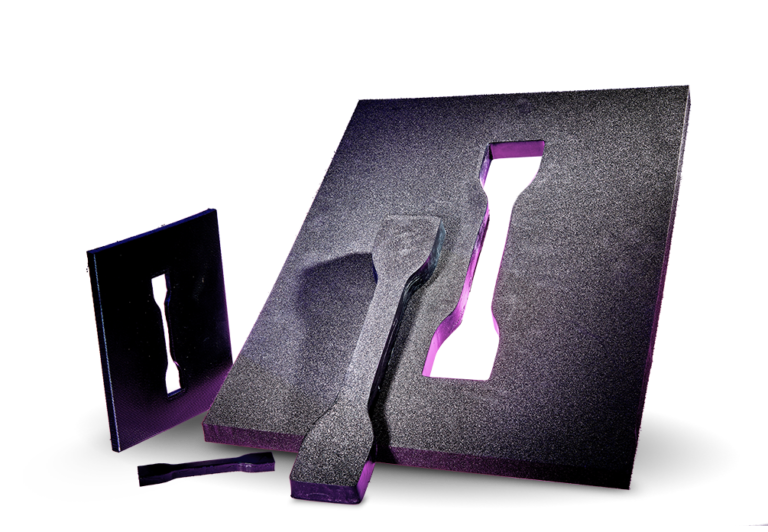

Extrusion and crosslinking

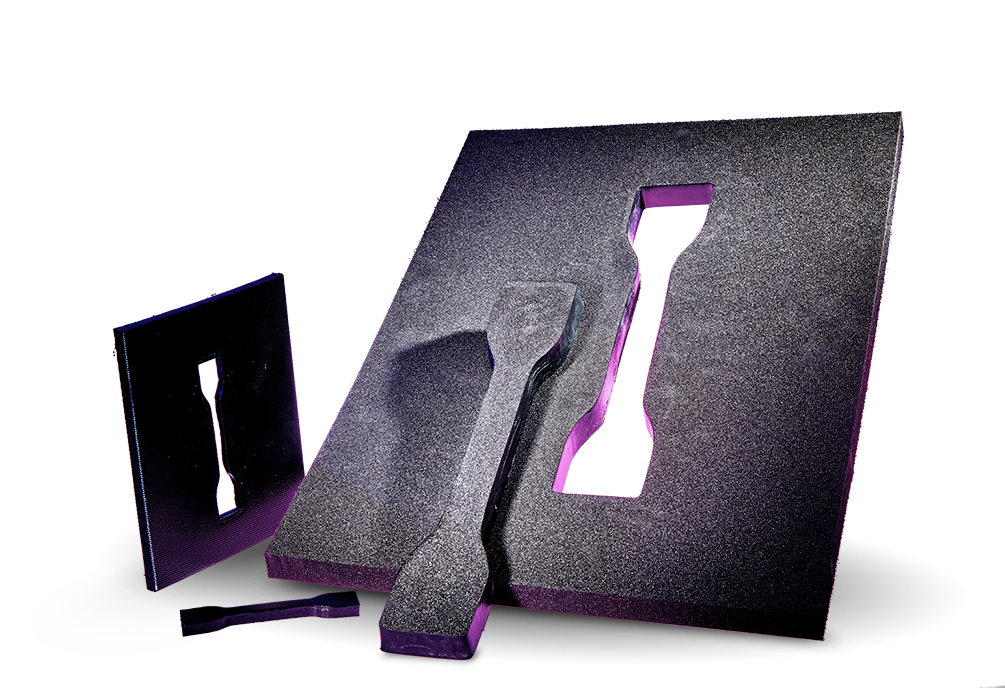

Polymer and any additives (colours, fire retardants, conductive agents) are extruded into a continuous solid plate. The plate passes through an oven, which activates the crosslinking process. The plate then cools and is cut into slabs.

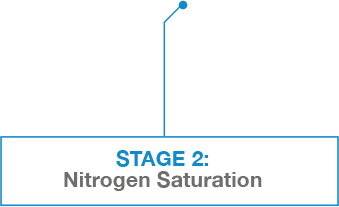

Stage 2

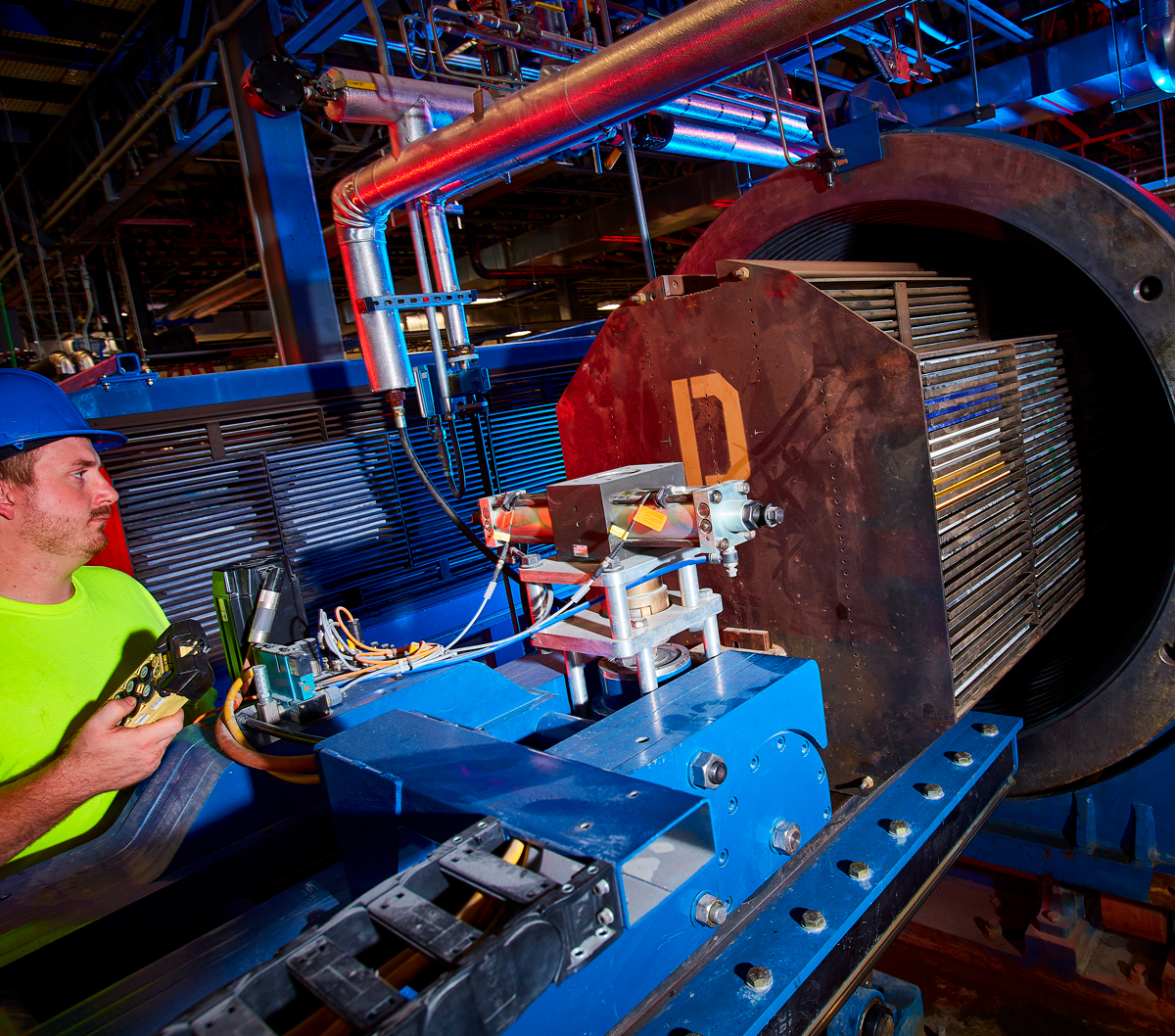

Nitrogen saturation

Slabs are loaded into a high-pressure autoclave. The material is heated above its melting point and pressurised with pure nitrogen gas. Over a long period of time the nitrogen gas diffuses into the slabs. A rapid depressurisation destabilises the absorbed nitrogen, nucleating cells in the slab. The slabs are then cooled under pressure in the autoclave, locking the nitrogen in the un-expanded slabs, prior to them being unloaded. Operating temperatures reach up to 250ºC / 482ºF and pressures 675 bar / 10,000 psi.

Stage 3

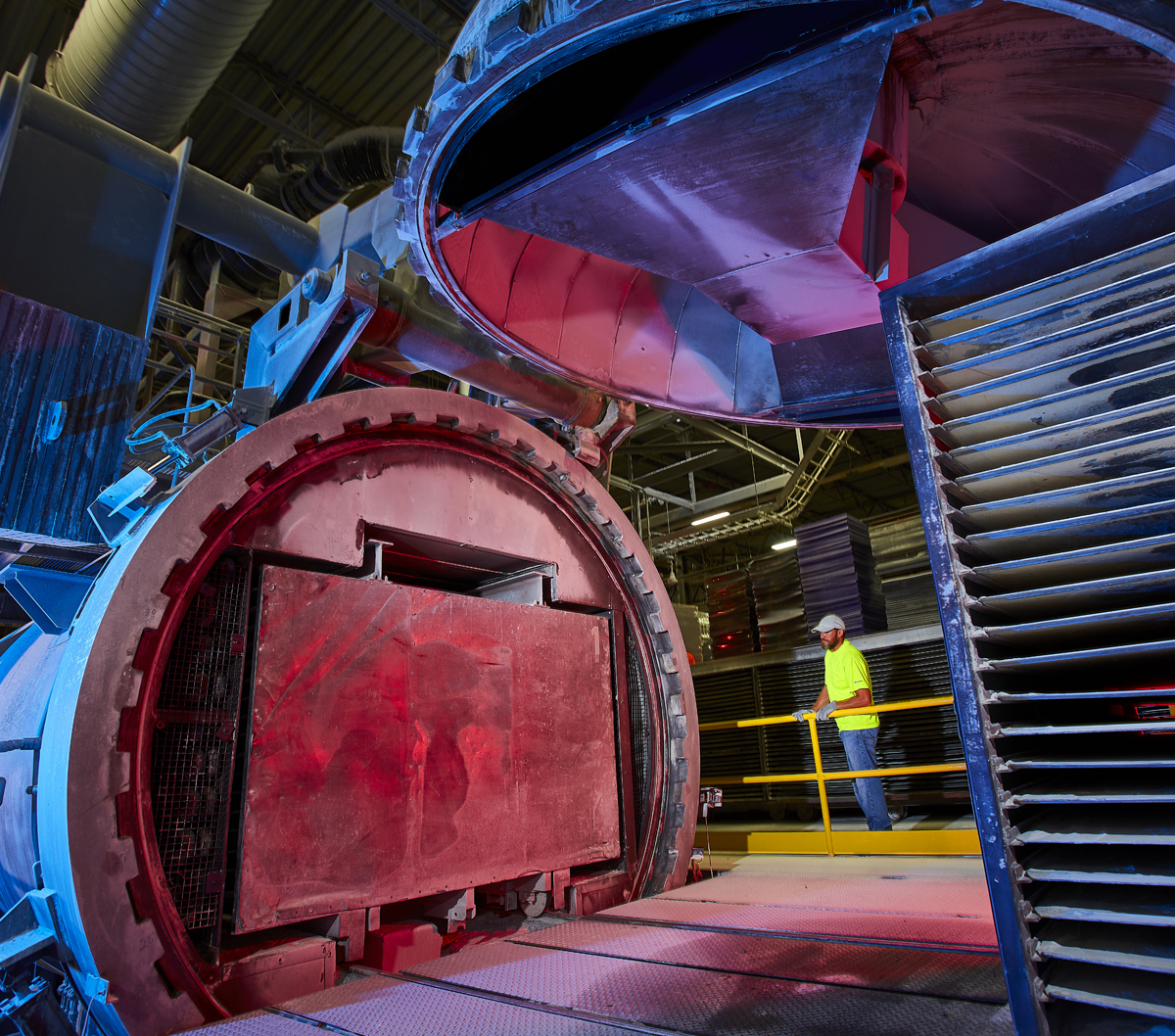

Expansion

The nitrogen-charged slabs are loaded into a large lower-pressure autoclave and, under moderate pressure, are heated above their melting point. When the pressure is reduced the nitrogen expands, turning the slab into a larger foam sheet. This expansion process is unconstrained and so uniform in each dimension. Operating temperatures reach up to 250ºC / 482ºF and pressures 17 bar / 250psi.

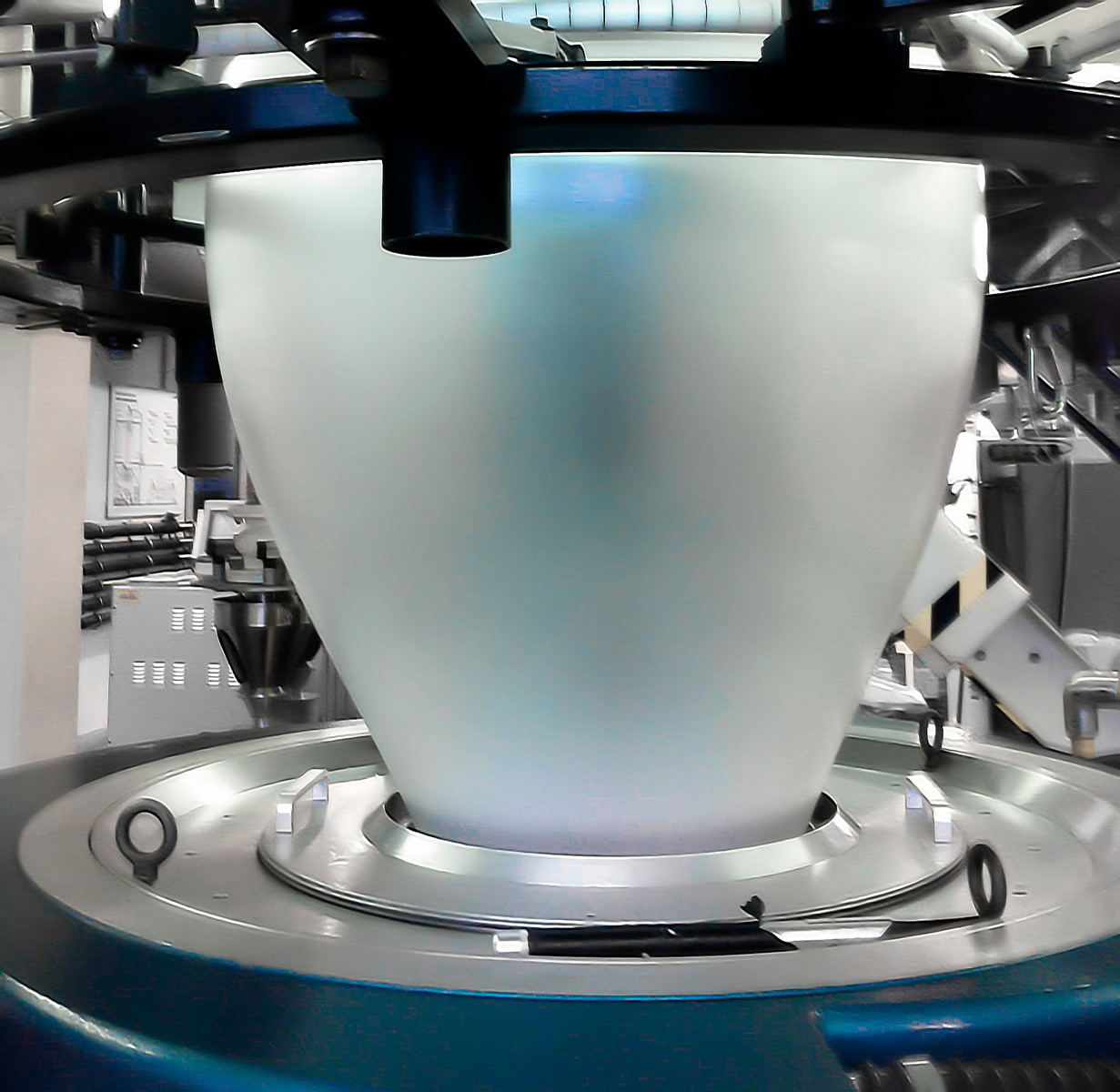

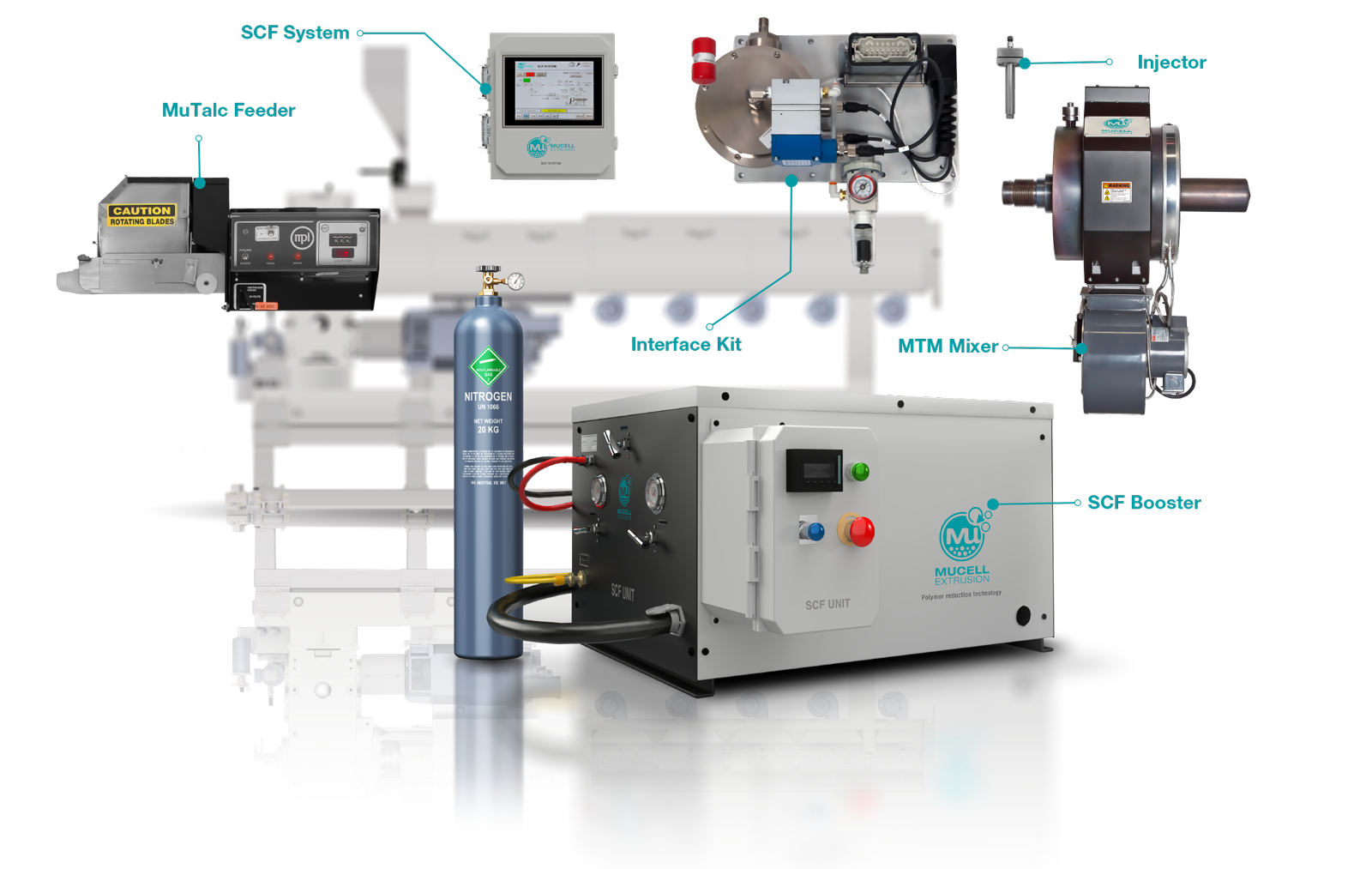

Polymer Reduction Technology

Patented technology from MuCell Extrusion LLC creates a lightweight centre in plastic extrusions by injecting pure atmospheric gas during manufacture. The result is a microcellular, or foamed, core within a solid skin – a single material that looks and performs like a solid plastic yet uses 15-20% less polymer.

Sheet applications

- Sheet for form-fill-seal (FFS) applications

- In-line thermoforming

- HDFT

- Sheets for signs and displays

- Sheets for construction

- Low-density sheets for gaskets and seals

Film applications

- Lamination films

- Stand up pouches

- Collation shrink film

- Agriculture

- Pet food bags

- Surface protection

MuCell polymer reduction technology can be applied in a wide range of extrusion applications. These materials are then used to make products, such as pouches, sachets, trays, pots and other containers frequently used in volume in consumer packaging, reducing the carbon footprint right through the supply chain. And, after use, the products can be recycled in standard post-consumer waste streams.

Find out more