Zotefoams makes history at Foam Expo Europe 2019 as it unveils groundbreaking technologies

Zotefoams today premieres its latest innovations from leading ranges, AZOTE® polyolefin foams and ZOTEK® high-performance products (HPP), including one of the most significant developments in crosslinked polyethylene foams (PE) for over three decades.

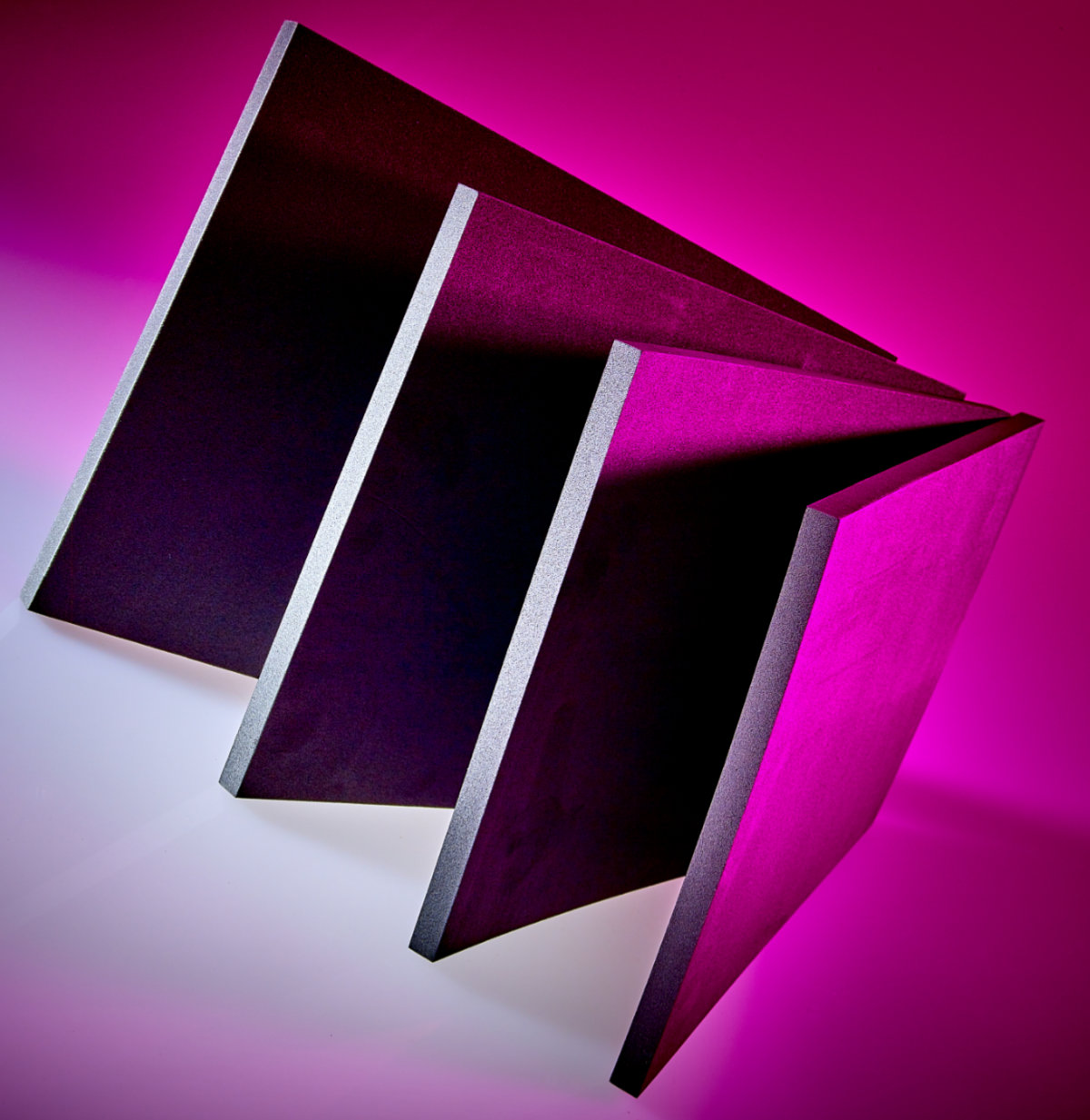

AZOTE® Adapt

As the world’s largest manufacturer of crosslinked polyolefin block foams, Zotefoams is proud to introduce AZOTE® Adapt – the newest addition to its AZOTE range and one of the most revolutionary technologies in 30 years.

AZOTE Adapt is a range of crosslinked PE foams with a fine cell structure, excellent consistency and low odour. It couples Zotefoams’ knowledge of foam processing using autoclaves with the latest blowing agent technology in a proprietary process that redefines chemical foaming. AZOTE Adapt is currently available on limited release in 30 and 45kg/m3 black grades with a matt black available soon.

The AZOTE® range incorporates many grades and densities, including the world’s lightest FR grade closed cell cross-linked foam at only 15kg/m³, and is available in different variants, including sheets and rolls. Each foam is formulated to satisfy a specific range of applications for a variety of markets including automotive, aerospace, product protection, medical, construction, sports and leisure.

Recently added AZOTE packaging grade LD30LX will also be on show at Foam Expo Europe. Offering a soft touch and fine cell size of just 0.4mm, LD30LX guarantees the aesthetic appeal and ultimate product protection required for luxury goods, making it ideal for product display and optimum presentation.

Furthermore, visitors to stand 654 will see the launch of Zotefoams’ latest thermoplastic elastomer (TPE) as the company extends its exclusive line-up of ZOTEK® foams. Manufactured from speciality elastomer, TPE displays excellent high- and low-temperature resistance, energy return, ease of thermoforming, chemical and abrasion resistance, and much more. Its physical and chemical properties make it the ideal alternative to current foamed rubber, silicon or solid TPE solutions, such as those in the automotive sector, offering cost and weight reductions to the market.

Zotefoams will present a special product showcase (Wednesday 11 September at 14:00hrs, stand 654) led by Director of Technology and Development, Dr Karl Hewson, demonstrating how its unique manufacturing process produces products from speciality thermoplastic elastomers (TPE’s), providing an alternative to traditional rubbers and a cost-effective, high performance replacement.

Zotefoams Group CEO, David Stirling, comments, “This is an exciting time for Zotefoams and we are really looking forward to bringing our latest innovations to Stuttgart. With all capacity investments due to be complete by mid-2020, we are in a great position with clear opportunity to grow the business further as we continue to demonstrate our commitment to meet growing demand with our revolutionary product offerings.”