Squaring the circle:

from 100%

recyclable

to fully circular

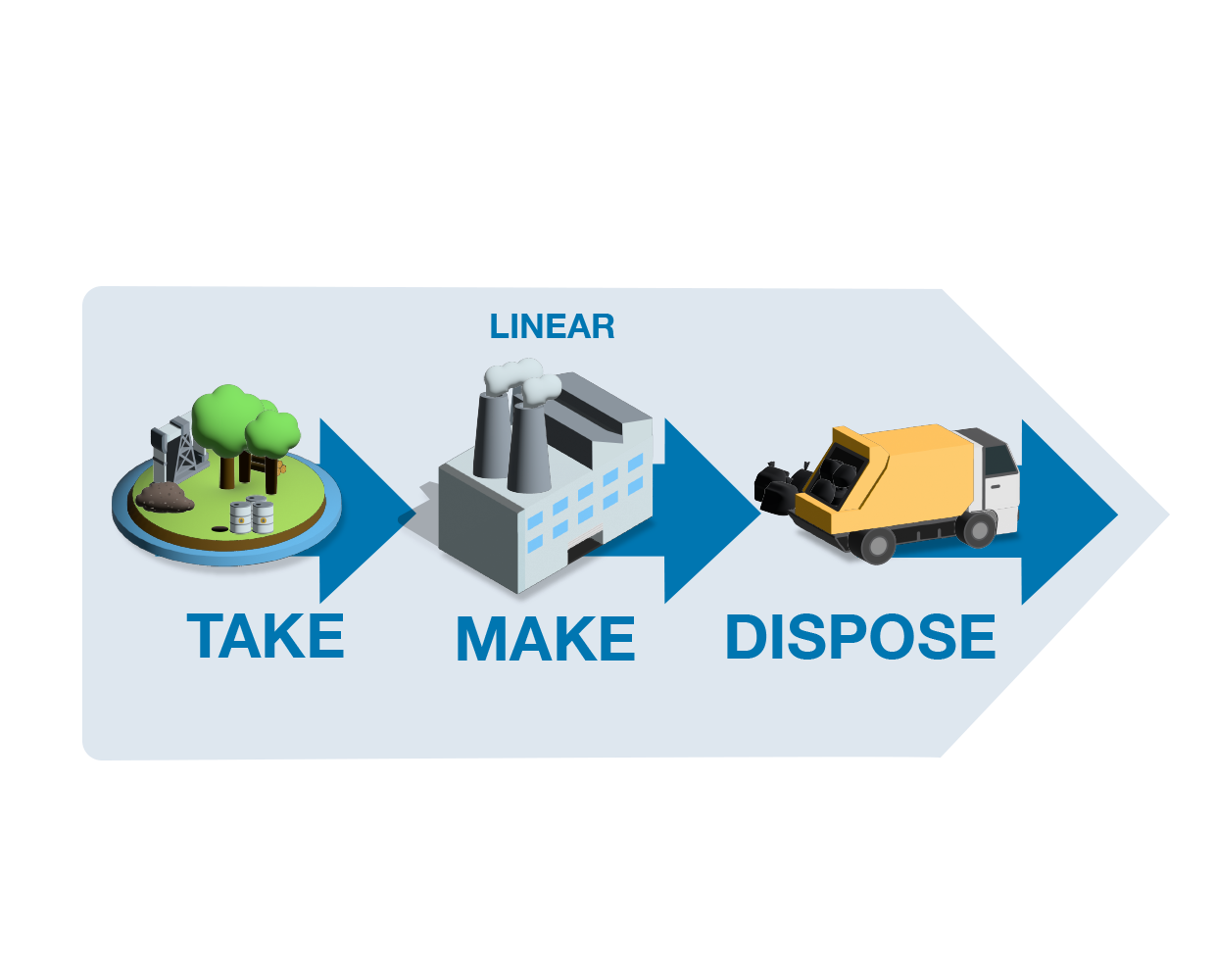

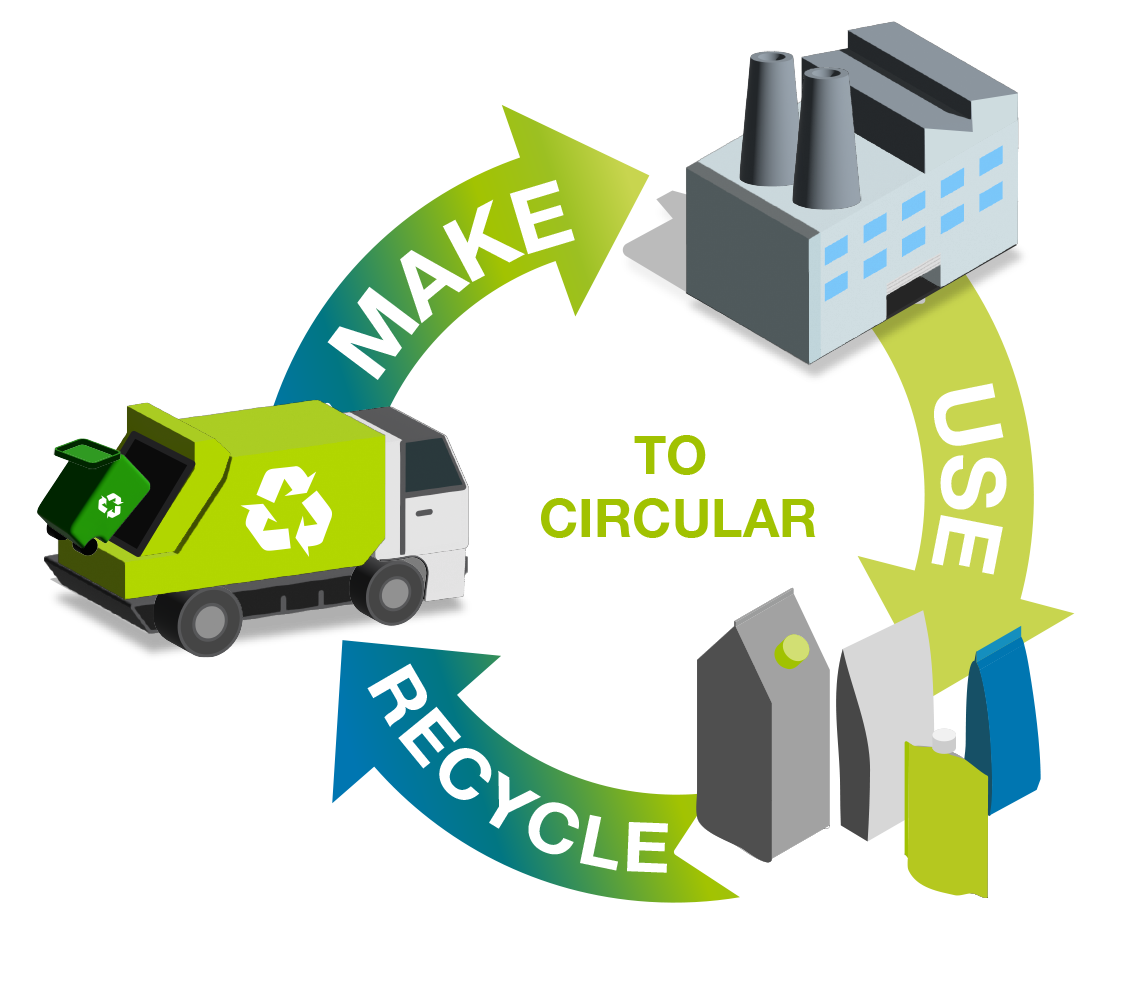

There are many reasons why the move from the linear ‘take-make-waste’ economy to a circular model where reuse is prioritised is an imperative. Climate change, waste and pollution – the scale of all these challenges can be reduced by embracing circularity.

Menu