MGR Foamtex (Thame, UK) is Europe’s leading supplier of advanced aircraft cabin upholstery systems, working with all major seat manufacturers as well as the world’s leading airlines.

Satisfying customers requires continuous innovation and to achieve this, the company needs to work with the best materials and suppliers.

David Howgego, Business Development Manager at MGR Foamtex, says that the strategic relationship with Zotefoams is key to the company’s success. Zotefoams’ ZOTEK® F OSU range of high-performance lightweight aviation foams produced from PVDF have been used in the advanced MGR SoftWall® panel system for over a decade – this unique vertical soft wall panel system is designed to cocoon the passenger, increasing comfort and deadening sound.

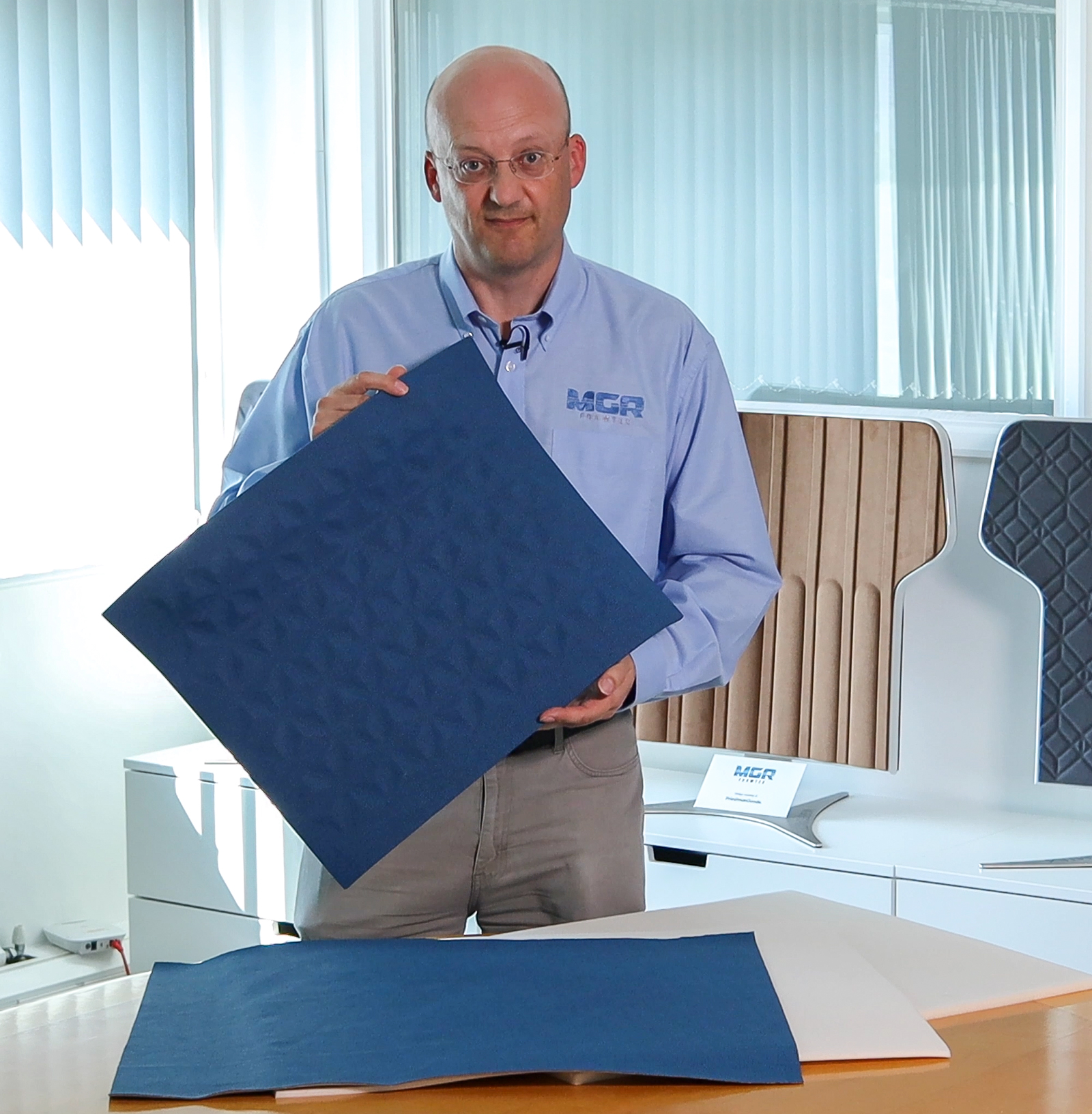

David Howgego, Business Development Manager at MGR Foamtex

The latest addition to the ZOTEK F OSU range – the Extra-Rigid XR grade – is the backbone of the new MGR SoftWall NextGen range, which, says David Howgego, is all about weight reduction. As a semi-structural foam, ZOTEK F OSU XR allows MGR Foamtex to offer all the benefits of MGR SoftWall but at half the weight.

Advanced Zotefoams materials are used to create many components, in this case a bespoke backshell for a business class seat. The key element is the XR grade foam, which replaces the traditional solid thermoplastic structure to achieve significant weight savings. During the manufacturing process, this is overlaid with a decorative front layer made from ZOTEK F SR (Semi-Rigid) Decorative front layer is made from SR and finally a face fabric is applied to produce the finished MGR SoftWall NextGen panel.

Ross Latham, Deputy Engineering Manager at MGR Foamtex, emphasises the importance of the company’s close partnership with customers to achieve a high-quality bespoke finished product, with constant communication, agreed milestones and assembly trials. Most parts, he says, include at least two grades form the ZOTEK F OSU range.

The process begins with vacuum forming a flat sheet of XR. “ZOTEK F OSU XR is a welcome alternative to solid thermoplastics that offers comparable rigidity but with a weight saving of 50%,” says Ross. “With aviation heavily focused on weight saving and greener flight, this is a very attractive proposition for our customers.”

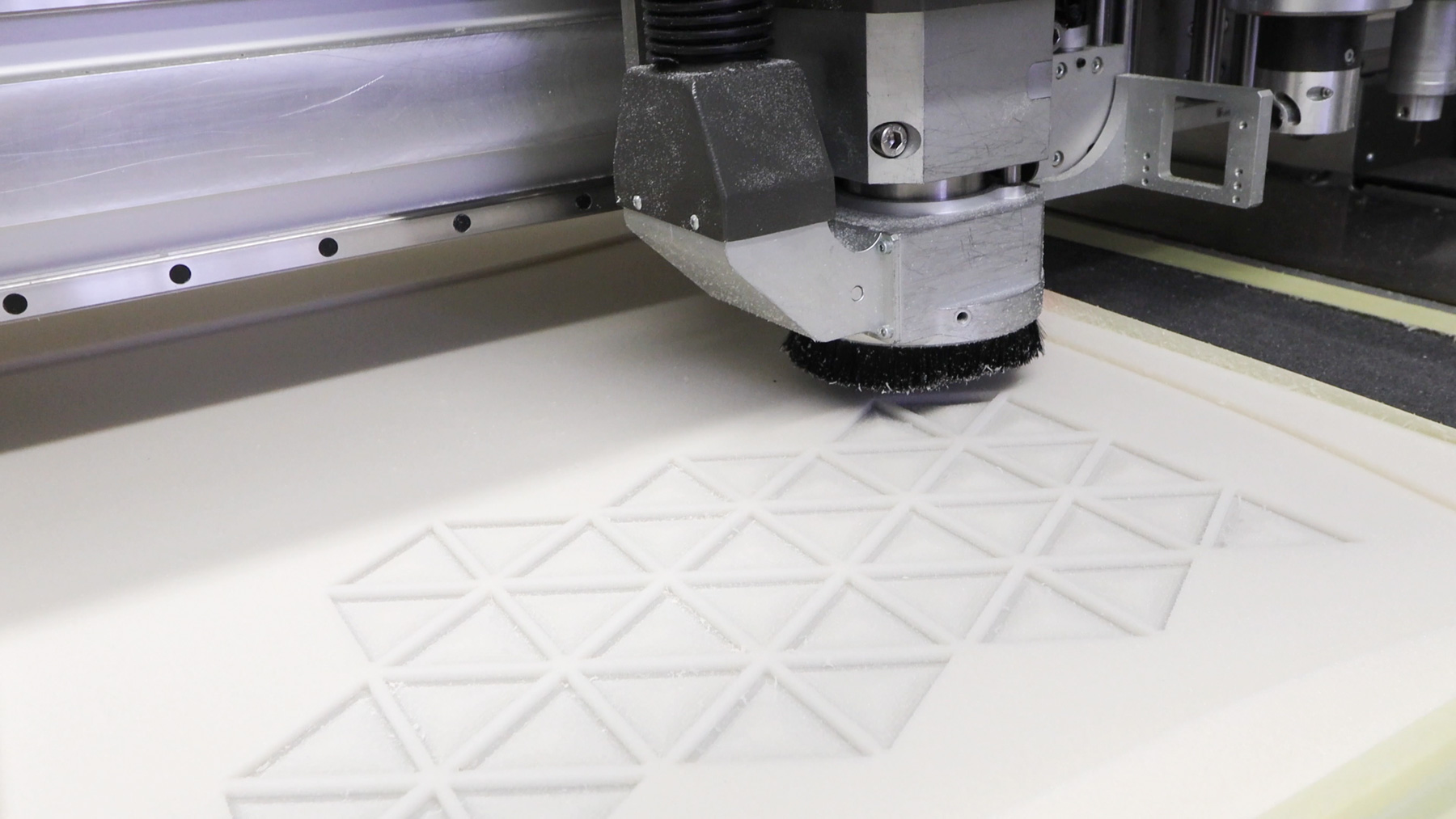

Working with customers, 3D CAD is used to create and refine designs that add individuality and a luxurious feel to Business and First Class cabins. Once approved, the design is applied to the ZOTEK F OSU SR via CNC routing.

From here, MGR Foamtex’s expert craftsmen hand finish each part in a process known as trimming. Using specialist adhesives, the two layers of ZOTEK F are bonded together before the chosen face fabric is applied, bringing the bespoke designs to life.

The result – MGR SoftWall NextGen: 50% lighter thanks to Zotefoams’ unique ZOTEK F materials.

For more information on ZOTEK F OSU high-performance foams for aviation and aerospace, visit https://www.zotefoams.com/zotek-f-osu-aviation-aerospace/

For more information on MGR SoftWall® NextGen, visit https://www.mgrfoamtex.com/softwall

MGR SoftWall® is a trademark of MGR Foamtex Limited