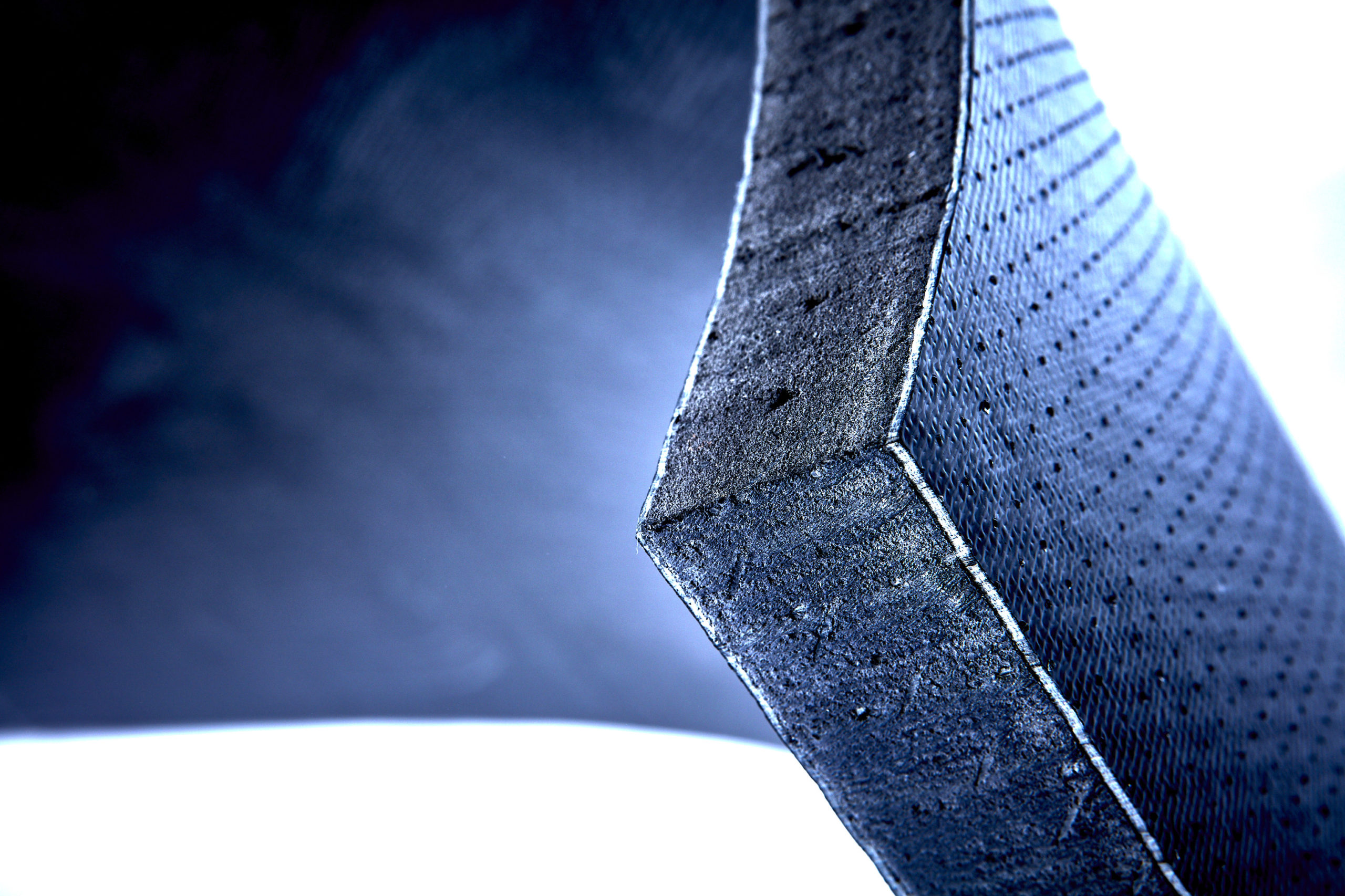

Foams for automotive interiors, engine bays and electric vehicles

Zotefoams produces lightweight foams of unique and unrivalled quality, delivering damping, insulation, seals and interior trim par excellence for the automotive sector.

The company’s closed cell crosslinked foams are produced from a wide range of polymers, including polyolefins, PVDF, nylon and thermoplastic elastomers.

Each delivers a range of acoustic, thermal and energy management properties suitable for different applications, in the interior, the engine bay, or as a sandwich material for composite cores.

Polyolefin foams in the AZOTE® family and foams made from engineering polymers under the ZOTEK® banner are all manufactured using Zotefoams unique three-stage process, which uses only temperature, pressure and nitrogen borrowed from the atmosphere.

The resulting materials are prized for their consistency, durability and superior performance to weight ratio – which means less weight and less material compared to components produced from chemically expanded foam, silicon or rubber. Less weight means reduced fuel/energy consumption and increased range.

The absence of VOCs from Zotefoams’ process produces further desirable qualities: foams are odour-free and isotropic, meaning that they do not exhibit any loss of integrity due to outgassing over time of chemical blowing agents

The origins of the Zotefoams process date back over a century and its products – notably Plastazote®, a polyethylene foam range introduced in 1962 and now part of the AZOTE family – have long been used by the leading automotive brands the world over.

Today the Plastazote range incorporates a vast range of densities, from 15kg/m3 (the world’s lightest closed cell crosslinked foam) to 115kg/m3, and a choice of properties including fire retardance, conductivity or static dissipation.

Foams compliant with standards including FMVSS 302, ECE R100 (electric vehicles) and ECE R118 are included and the sheer versatility of the AZOTE range – which also includes Evazote® ethylene copolymer foams – lends itself to the production of an array of automotive components.

For the toughest applications, high-performance foams in the ZOTEK range are an excellent choice for heat management, such as in battery assemblies, resistance to chemicals and outstanding energy absorption or return. ZOTEK materials carry many best-in-class standards certifications, such as UL 94 V-0 (flammability) for EV battery applications, and UL 723 0/0 for flame spread/smoke development.