AZOTE® core to Padel boom

Padel is set to become the sport of the third millennium and once again, AZOTE proves to be a winner.

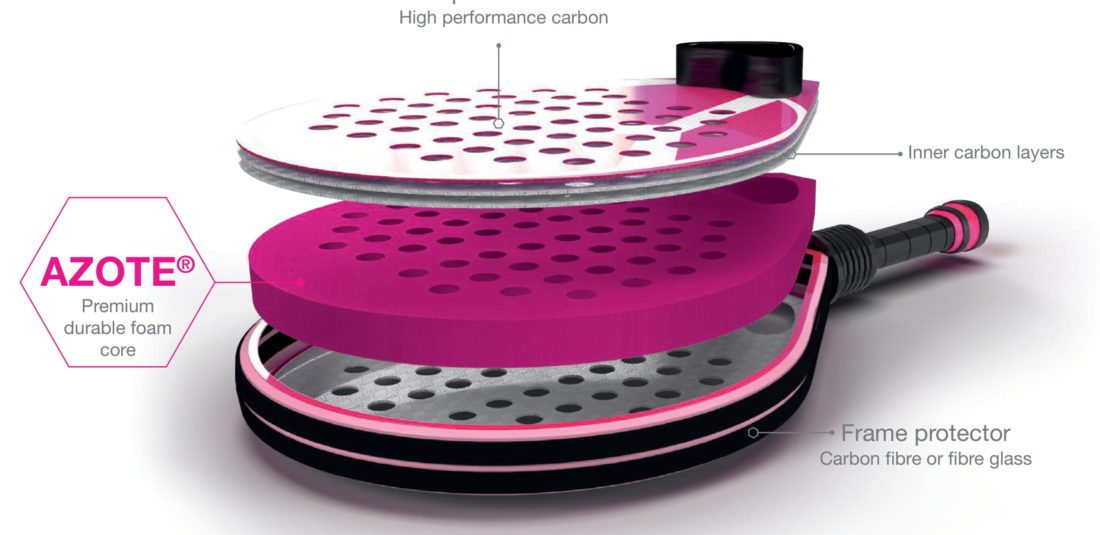

Zotefoams’ materials are proving to be the ideal choice for the central foam core of Padel rackets. The innovative AZOTE closed cell polyolefin foams product family is ideally suited to this application due to its high impact absorption and uniform density, which brings critical predictability in performance.

Since the 1970s, Padel has grown as a sport and now boasts over eight million players globally. Originating in Mexico, Padel is widely considered as the fastest growing sport in the world, and with many elite tennis players also enjoying Padel, there is no sign of this trend slowing.

Padel is simple to learn and the court size (one third the size of a tennis court) makes conversation easy, giving the game a more social feel. It is normally played in doubles on an enclosed court where the walls add a great dynamic to the game, allowing for trick shots and some massive rallies.

The rackets (or paddles) are very much adapted for the sport. They have holes instead of strings and come in several shapes and weights. Each racket has a foam core – essential to reduce uncomfortable vibration that would be particularly problematic for players who suffer from arm pain, such as tendonitis, or shoulder problems.

Thanks to Zotefoams’ unique manufacturing process, AZOTE foams offer unrivalled consistency in cell size and density, giving the all-important predictability of response and protection that makes it the material of choice for a wide range of sports and leisure applications.

AZOTE is the group brand name for Zotefoams’ closed cell, cross-linked polyolefin foams used within the racket. These high-quality foams are produced from differing base polymers but all manufactured using unique autoclave processes.

AZOTE foams are characterised by:

- consistent cell size and structure

- outstanding purity

- exceptional isotropic physical performance

- extremely low odour

Each AZOTE foam is formulated to satisfy a specific range of applications. They represent the best-in-class solution for the desired range of mechanical characteristics such as impact absorption and also deliver:

- colour uniformity

- ease and consistency in fabrication

- uniform density

- predictability in performance