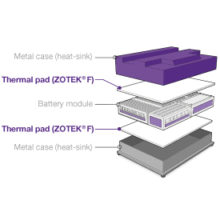

ZOTEK® F

ZOTEK® F foams are inherently flame retardant releasing very little heat and only small quantities of smoke during combustion. They are biologically inert and offer:

Automotive

The ideal material for under the hood applications. With UL94 V-0 flammability rating, excellent compression strength and thermal insulation.

Manufactured via Zotefoams’ unique method, ZOTEK® F has negligible VOC content and is typically 10-15% lighter than any competing material.

Commercial, business and military aircraft and aerospace industries

● Zotefoams T-FIT® range advanced industrial tube and pipe insulation systems

● For Semiconductor & pharmaceutical clean-room environments (sealing and insulation applications)

● Electronics industries

● Industrial applications such as chemical engineering, pharmaceutical production, and medical equipment

● High specification building and construction projects where UV resistance is key

Copyright © 2024

AZOTE®, ZOTEK®, T-FIT®, Plastazote®, Evazote®, Supazote®, ReZorce®, Refour® and Ecozote® are registered trademarks of Zotefoams plc

MuCell® is a registered trademark of Trexel Inc.